Outline

The grading of agricultural products after harvest consists of external quality based on color, size, weight, shape and internal quality based on sugar content, acidity, internal defects. Camera technology, which is mainly used for external quality, is one of the key technologies for automatic the processing process as well as objective grading of agricultural products. LifNTech has developed a multi-channel camera sorting technology to more accurately measure the color and shape of agricultural products and a high-speed algorithm for high-capacity processing. We have already developed total sorting technology for various agricultural products such as pepper, garlic as well as apple, pear.

Mult-Channel Camera Technoogy

The color, size, and shape of agricultural products differ not only according to the individuals but also because they are different even in the case of the same individuals. Therefore, in order to sort more accurately, multi-channel camera technology is required to analyze images of different parts. This multi-channel camera technology enables accurate size, volume and shape sorting.

|

|

|

Color & Shape Measurement

The sorting using cameras will determine objective grades through color and shape quantification. However, color is totally different depending on the light source or measurement sensor, so you need to perform a color calibration process for correct sorting.

|

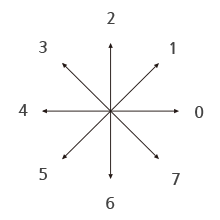

|

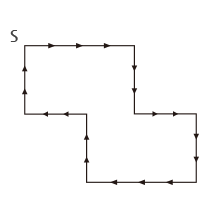

Chain Coding chain code : 0 0 0 6 6 0 0 6 6 4 4 4 4 2 2 4 2 2 shape no : 0 0 0 6 0 2 6 0 6 0 0 6 0 2 0 6 0 6 |

| (a) chain-code | (b) figure |

Internal & External Defect Detection

The defects must be sorted out in advance, as they detract from the merchandise and storability of agricultural products. However, it is not easy to discriminate with the naked eye, and there are various limitations in the sorting. The LifeNTech provide optimal solution to detect defects in agricultural products by using various physical properties such as density, vibration, sound wave characteristic as well as defect color and NIR spectral characteristic.

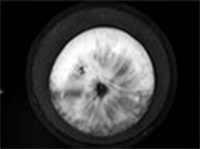

Detection Example of internal defects in apples using NIR images

Because, unlike the visible light(Color, 550nm), NIR rays (X1, X2) are not affected by the surface color, it is possible to make the image area only for the defect area even without complicated pre-processing.

|

|

|

|

| Color | 500nm | x1nm | x2nm |